When planning a home renovation or construction project, one common concern is whether the materials used can bear the weight of everyday household items, particularly heavy furniture. MgO subfloor sheathing board is a modern building material praised for its strength, fire resistance, and eco-friendliness, but many homeowners and contractors wonder: can MgO subfloor sheathing board support heavy furniture?

What is MgO Subfloor Sheathing Board?

MgO (magnesium oxide) subfloor sheathing board is an engineered building panel primarily made from magnesium oxide, magnesium chloride, and other mineral fillers. Its composition gives it several advantages over traditional plywood or OSB subflooring:

- High Strength: MgO boards have impressive compressive and flexural strength, allowing them to withstand significant loads without warping or breaking.

- Fire Resistance: Unlike conventional wood-based subfloor materials, MgO boards are non-combustible, making them ideal for safety-conscious construction.

- Moisture Resistance: MgO subfloor boards resist mold and mildew, which is especially useful in areas prone to humidity or spills.

- Eco-Friendly: They are made from natural minerals and often contain recycled materials, providing a more sustainable option than wood-based products.

While these characteristics make MgO subfloor sheathing boards highly desirable, the question of whether they can handle heavy furniture involves a deeper look into load-bearing capacity and proper installation.

Understanding Load-Bearing Capacity

The ability of any subfloor to support weight depends on several factors:

- Board Thickness and Density: MgO subfloor boards are available in different thicknesses, typically ranging from 1/2 inch (12 mm) to 1 inch (25 mm). Thicker and denser boards naturally provide greater support.

- Joist Spacing and Support: The subfloor alone does not bear all the weight; the underlying joists play a critical role. Standard residential joist spacing ranges from 12 to 24 inches. Closer spacing increases load-bearing capacity.

- Type of Furniture: Heavy furniture like cabinets, bookshelves, or pianos can exert concentrated loads. A properly supported MgO subfloor distributes weight effectively but may need additional reinforcement under very heavy items.

- Installation Method: Proper fastening with screws or nails, as well as the use of adhesive where appropriate, ensures the subfloor performs at its best.

How MgO Subfloor Handles Heavy Loads

Compressive Strength

MgO subfloor boards have a high compressive strength, often exceeding 40 MPa (megapascals). Compressive strength indicates how much weight per unit area a material can support without crushing. For context:

- A typical residential load, including heavy furniture, is far below the compressive strength of MgO boards.

- Even concentrated loads from heavy furniture are unlikely to cause the board to fail if it is properly supported by joists and installed according to manufacturer specifications.

Flexural Strength

Flexural strength measures how much a material can bend before breaking. MgO subfloor boards usually exhibit flexural strength values between 7–10 MPa, which is sufficient for residential flooring when paired with standard joist spacing. A board with good flexural strength will resist sagging under the weight of heavy furniture.

Impact Resistance

Though MgO boards are strong, they are also more brittle than plywood in terms of sudden impact. Dropping extremely heavy furniture or exerting sharp point loads may risk cracking if the weight is concentrated on a small area. Using protective furniture pads or distributing the weight with plywood or other underlayment can mitigate this risk.

Installation Tips for Supporting Heavy Furniture

Even the strongest subfloor will underperform if installed incorrectly. To maximize load-bearing capability, consider these guidelines:

- Choose the Right Thickness: For areas expected to bear heavy furniture, use MgO boards that are at least 3/4 inch (18 mm) thick.

- Use Proper Fasteners: Screws are generally preferred over nails for subflooring because they resist pull-out better and provide consistent fastening. Ensure screws are compatible with MgO boards to avoid cracking.

- Adhere to Joist Spacing Recommendations: For heavy load zones, reduce joist spacing to 12 inches rather than the maximum 16–24 inches commonly used in residential construction.

- Add Blocking or Reinforcement: Placing additional support beams or cross-blocking between joists under extremely heavy furniture helps distribute weight and prevents sagging.

- Level and Smooth Installation: Any unevenness can concentrate stress in certain areas, which increases the risk of cracking. Ensure the subfloor is level and joints are staggered for optimal load distribution.

Real-Life Performance

Several construction professionals have reported excellent performance of MgO subfloor boards in homes, offices, and commercial buildings. Key observations include:

- Standard MgO boards can support bookcases, dining tables, and sofas without noticeable deflection.

- Areas with extremely heavy items, like pianos or large appliances, sometimes benefit from additional reinforcement but rarely require a complete redesign of the subfloor.

- Moisture-resistant properties ensure that even under long-term load, the board maintains its structural integrity better than traditional wood-based subfloors in humid environments.

Tips for Heavy Furniture Placement

To further ensure the longevity of your MgO subfloor and prevent damage from heavy furniture:

- Use Furniture Pads: Place felt or rubber pads under legs to distribute weight evenly.

- Avoid Concentrated Loads: Refrain from placing extremely heavy items on one small area. If unavoidable, consider reinforcing that section.

- Regular Inspection: Over time, inspect for any sagging or cracking. Early detection allows you to add support before more serious issues arise.

- Distribute Load Across Multiple Joists: Position heavy furniture so that its weight spreads over more than one joist whenever possible.

Comparing MgO to Other Subfloor Materials

Understanding how MgO compares to other subfloor options highlights its advantages:

| Material |

Compressive Strength |

Moisture Resistance |

Load-Bearing Performance |

Fire Resistance |

| Plywood |

30–40 MPa |

Low |

Good with joist support |

Low |

| OSB |

25–35 MPa |

Low-Moderate |

Good with joist support |

Low |

| MgO Board |

40–60 MPa |

High |

Excellent with proper installation |

High |

As the table shows, MgO boards provide superior fire and moisture resistance while supporting comparable or higher loads than traditional materials.

Common Misconceptions

-

“MgO subfloor will crack under any heavy weight.”

While MgO is mineral-based and harder than wood, it is engineered to resist cracking under typical residential loads when installed correctly.

-

“You must avoid placing furniture on MgO subfloor.”

In reality, properly installed MgO subfloor can handle furniture like beds, sofas, and cabinets without issue. Extra precautions are only needed for very concentrated or extreme loads.

-

“Only plywood is safe for heavy furniture.”

This is outdated thinking. Modern MgO subfloor boards can outperform plywood in strength, moisture resistance, and fire safety.

Conclusion

MgO subfloor sheathing board is more than capable of supporting heavy furniture when correctly installed. Its high compressive and flexural strength, combined with proper joist spacing and installation techniques, ensures that common household furniture can be placed without concern. For extremely heavy items, reinforcement or load distribution strategies can be used to enhance safety.

The additional benefits of moisture resistance, fire safety, and environmental friendliness make MgO subfloor an excellent choice for modern residential and commercial construction. By understanding the properties of MgO boards and following installation best practices, homeowners and contractors can confidently use this material as a strong, durable, and long-lasting foundation for their interiors.

BMSC 517 New Sulfate MgO Board

BMSC 517 New Sulfate MgO Board Multi-Support MgO Wall Sheathing Board

Multi-Support MgO Wall Sheathing Board Perseverance MgO Wall Sheathing Board

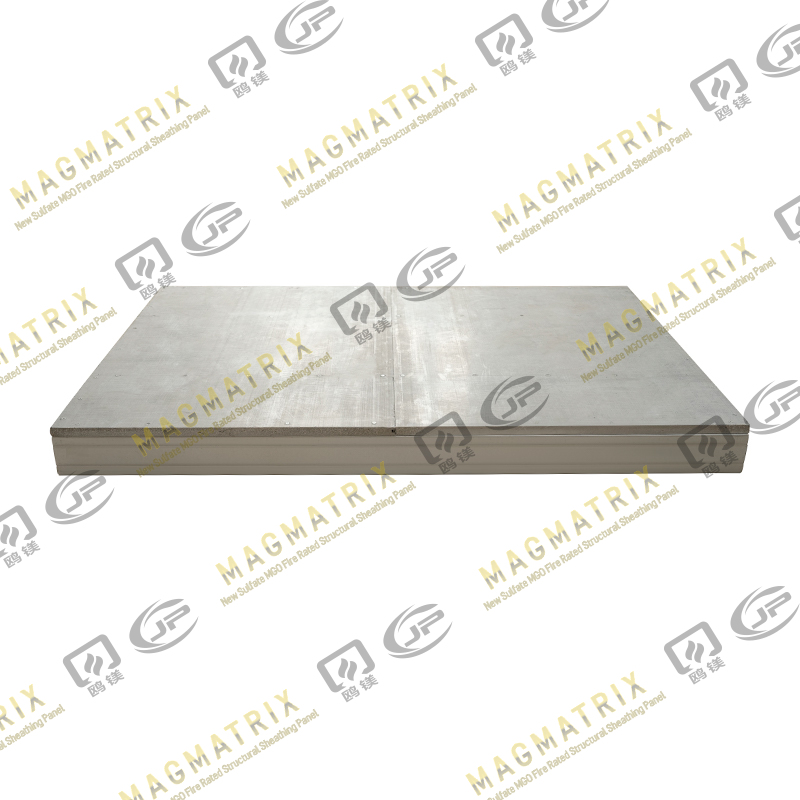

Perseverance MgO Wall Sheathing Board Multi-Support MgO Subfloor Sheathing Board

Multi-Support MgO Subfloor Sheathing Board Perseverance MgO Subfloor Sheathing Board

Perseverance MgO Subfloor Sheathing Board MagMatrix MgO Underlayment Panel/board

MagMatrix MgO Underlayment Panel/board

English

English русский

русский Español

Español